tel:

+86 512 5881 3235email:

stm@st-machinery.com

1. Bend-arm (C-axis) by AC servomotor.

2. Clamp die by hydraulic; pressure die by hydraulic.

3. Carriage (Y-axis) by AC servomotor.

4. With rear booster driven by AC servomotor.

5. Collets (B-axis): rotation by AC servomotor, grip by hydraulic.

6. With roll bending function (PUSH BENDING), can make big radius by rolling.

7. Tooling shift : motion up-down by hydraulic or AC servomotor with brake; left-right by AC servomotor.

8. PDA (pressure die assist): by hydraulic or AC servomotor.

9. Automatic moving parts lubrication.

10. Standing pedestal, serves emergency stop, double-hand startup and remote control.

11. Industrial PC (windows system) assorted with touch screen display, 3D preview, remote control, D bending simulation, collision prevention.

12. Optional: auto loading and unloading system.

| Model | STB-50CNC-4A/5A | STB-65CNC-4A/5A |

|---|---|---|

| Bending capability OD×WT (carbon steel) | Φ50.8×2.5 mm | Φ63.5×3 mm |

| Bending radius | 35~200 mm | 50~280 mm |

| Bending angle | 0~195° | 0~195° |

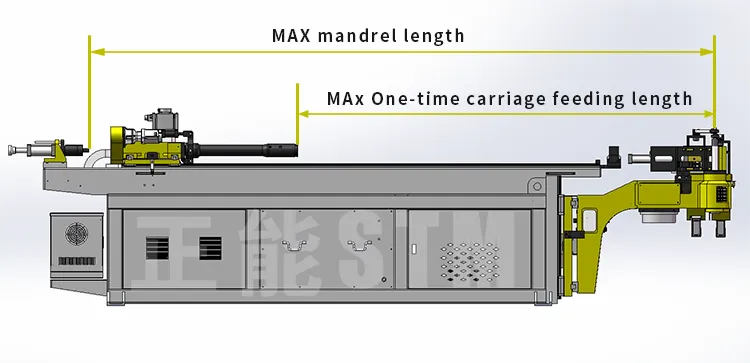

| Max bending length with mandrel | 2600mm | 3000mm |

| Bending speed | Max. 90°/sec | Max. 70°/sec |

| Bending accuracy | ±0.05° |

±0.05° |

| Feeding speed | 800 mm/sec | 500mm/sec |

| Feeding accuracy | ±0.1 mm | ±0.1 mm |

| Rotating speed | 240°/sec | 200°/sec |

| Rotating accuracy | ±0.1° | ±0.1° |

| Tools stack | 2 | 3 (including rolling tools) |

| Bending | Electric Servomotor | Electric Servomotor |

| Feeding/Booster | Electric Servomotor | Electric Servomotor |

| Rotating | Electric Servomotor | Electric Servomotor |

| Work head shift (horizontal) |

Electric Servomotor |

Electric Servomotor |

| Work head shift (vertical) |

Hydraulic / Electric Servomotor |

Electric Servomotor |

| Main motor power | 5.5 KW | 5.5 KW |

| System hydraulic pressure | 12MPa | 12MPa |

| Size | 5000×1400×1600mm | 5800×1400×1700mm |

| Weight | 3500 kg | 4200 kg |