-

tel:

+86 512 5881 3235 -

email:

stm@st-machinery.com

STB-10CNC-3A Super Fast Tube Bending Machine

STB-10CNC-3A Super Fast Tube Bending Machine

description1

Zipper closure

1/5 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the

body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them

in

place during workout

Description

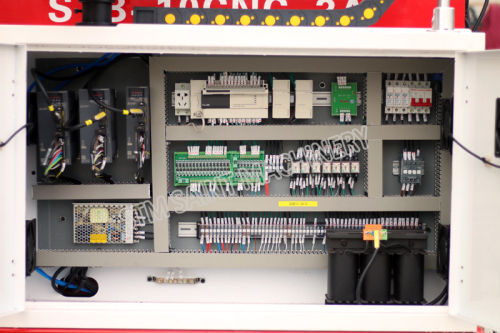

The body is made through welding, the mechanical part through assembly; using premuim pneumatic system and electronic control system.

1. Automatic CNC pipe bending machine;

2. Equipped with 3 programmable axis and one-stack tooling;

3. Feeding: servomotor drive with the ball screw; Rotation: servomotor drive with reducer (the servomotor from Mitsubishi J3/J4);

4. Bending: Servomotor bending with reducer;

5. Top brand pneumatic parts and Mitsubishi PLC unit;

6. Automatic lubrication system for moving areas (optional);

7. Self-diagnostic system, detecting the error immediately;

8. Multiple groups pipe-bending information storage;

9. Touch screen system and human/machine interface control provide user friendly operations;

10. Electric cabinet cooling fan and the hydraulic cooling system ensure the equipment long-time work stably under the high temperature.

1. Automatic CNC pipe bending machine;

2. Equipped with 3 programmable axis and one-stack tooling;

3. Feeding: servomotor drive with the ball screw; Rotation: servomotor drive with reducer (the servomotor from Mitsubishi J3/J4);

4. Bending: Servomotor bending with reducer;

5. Top brand pneumatic parts and Mitsubishi PLC unit;

6. Automatic lubrication system for moving areas (optional);

7. Self-diagnostic system, detecting the error immediately;

8. Multiple groups pipe-bending information storage;

9. Touch screen system and human/machine interface control provide user friendly operations;

10. Electric cabinet cooling fan and the hydraulic cooling system ensure the equipment long-time work stably under the high temperature.

Parameters

Application

Video