-

tel:

+86 512 5881 3235 -

email:

stm@st-machinery.com

Tube Bending (From Wikipedia)

Tube Bending (From Wikipedia)

Mar 12, 2015

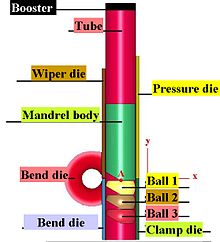

Tube bending as a process starts with loading a tube into a pipe bender and clamping it into place between two dies, the clamping block and the forming die. The tube is also loosely held by two other dies, the wiper die and the pressure die.

The process of tube bending involves using mechanical force to push stock material pipe or tubing against a die, forcing the pipe or tube to conform to the shape of the die. Often, stock tubing is held firmly in place while the end is rotated and rolled around the die. Other forms of processing including pushing stock through rollers that bend it into a simple curve.[2] For some tube bending processing, a mandrel is placed inside the tube to prevent collapsing. The tube is also held in tension by a wiper die to prevent any creasing during stress. A wiper die is usually made of a softer alloy i.e. aluminum, brass to avoid scratching or damaging the material being bent.

Much of the tooling is made of hardened steel or tool steel to maintain and prolong the tools life. However wherever there is a concern of scratching or gouging the work piece, a softer material such as aluminum or bronze is utilized. For example, the clamping block, rotating form block and pressure die are often formed from the hardened steel because the tubing is not moving past these parts of the machine. On the other hand, the pressure die and the wiping die are formed from aluminum or bronze to maintain the shape and surface of the work piece as it slides by.

Pipe bending machines are typically human powered, pneumatic powered, hydraulic assisted, hydraulic driven, or electric servomotor.

Press bending

Probably will be the first bending process used on cold pipes and tubing. In this process a die in the shape of the bend is pressed against the pipe forcing the pipe to fit the shape of the bend. Because the pipe is not supported internally there is some deformation of the shape of the pipe giving an oval cross section. This process is used where a consistent cross section of the pipe is not required. Although a single die can produce various shapes, it only works for one size tube and radius.

Rotary draw bending

Rotary draw bending (RDB) is a precise technology, since it bends using tooling or "die sets" which have a constant center line radius (CLR), alternatively indicated as Mean Bending Radius (Rm). Rotary draw benders can be programmable to store multiple bend jobs with varying degrees of bending. Often a positioning index table (IDX) is attached to the bender allowing the operator to reproduce complex bends which can have multiple bends and differing planes.

Rotary draw benders are the most popular machines for use in bending tube, pipe and solids for applications like: handrails, frames, motor vehicle roll cages, handles, lines and much more. Rotary draw benders create aesthetically pleasing bends when the right tooling is matched to the application. CNC rotary draw bending machines can be very complex and use sophisticated tooling to produce severe bends with high quality requirements. The complete tooling is required only for high-precision bending of difficult-to-bend tubes with relatively large OD/t (diameter/thickness) ratio and relatively small ratio between the mean bending radius Rm and OD.[3] The use of axial boosting either on the tube free end or on the pressure die is useful to prevent excessive thinning and collapse of the extrados of the tube. The mandrel, with or without ball with spherical links, is mostly used to prevent wrinkles and ovalization. For relatively easy bending processes (that is, as the difficulty factor BF decreases), the tooling can be progressively simplified, eliminating the need for the axial assist, the mandrel, and the wiper die (which mostly prevents wrinkling). Furthermore, in some particular cases, the standard tooling must be modified in order to meet specific requirements of the products.

Roll bending

During the roll bending process the pipe, extrusion, or solid is passed through a series of rollers (typically 3) that apply pressure to the pipe gradually changing the bend radius in the pipe. The pyramid style roll benders have one moving roll, usually the top roll. Double pinch type roll benders have two adjustable rolls, usually the bottom rolls, and a fixed top roll. This method of bending causes very little deformation in the cross section of the pipe. This process is suited to producing coils of pipe as well as long gentle bends like those used in truss systems.

Three-Roll Push Bending

The Three-Roll Push Bending (TRPB) is the most commonly used freeform-bending process to manufacture bending geometries consisting of several plane bending curves. Nevertheless, a 3D-shaping is possible. The profile is guided between bending-roll and supporting-roll(s), while being pushed through the tools. The position of the forming-roll defines the bending radius. The bending point is the tangent-point between tube and bending-roll. To change the bending plane, the pusher rotates the tube around its longitudinal axis. Generally, a TRPB tool kit can be applied on a conventional rotary draw bending machine. The process is very flexible since with a unique tool set, several bending radii values Rm can be obtained, although the geometrical precision of the process is not comparable to rotary draw bending.[4]

Bending contours defined as spline- or polynomial-functions can be manufactured.[5]

Simple Three-Roll Bending

Three roll bending of tubes and open profiles can also be performed with simpler machines, often semi-automatic and non CNC controlled, able to feed the tube into the bending zone by friction. These machines have often a vertical layout, i.e. the three rolls lie on a vertical plane.